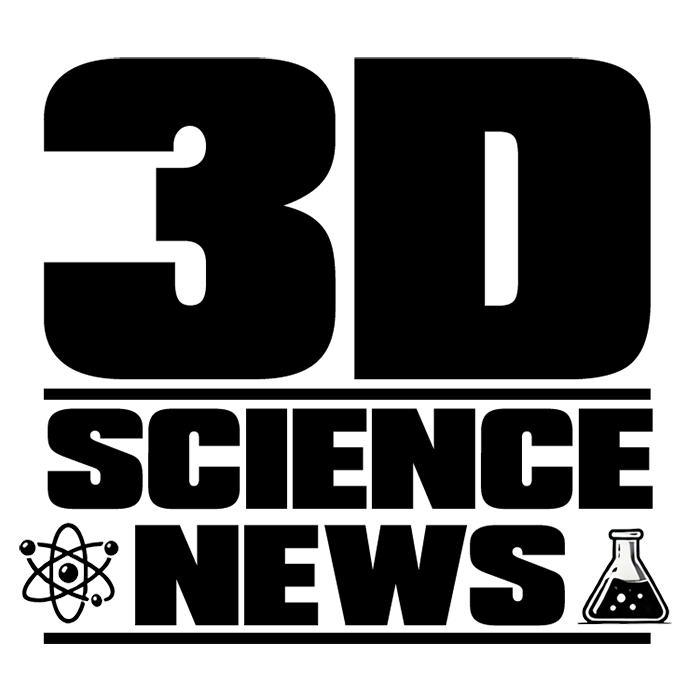

Spiders don’t just spin silk. They forge it. As they pull threads from their spinnerets with their hind legs, they’re not just reeling out a web—they’re weaponizing a material tougher than steel. The more they stretch it, the stronger it gets.

Northwestern University researchers wanted to know why. So they built a digital spider silk in a computer model and watched what happened at the molecular level—because, frankly, no microscope is good enough. Turns out, stretching aligns protein chains and increases the number of molecular bonds, fortifying the silk like a microscopic game of Tetris.

To prove the model wasn’t just virtual wizardry, the team engineered actual spider silk in a lab and tested it. It held up. This discovery could pave the way for artificial silk that’s stronger, stretchier, and—if scientists get really creative—possibly even bulletproof.

Because nature is showing off again.

Sinan Keten, Northwestern’s resident expert in bioinspired materials, explains that while scientists always knew stretching was key to silk’s strength, they never understood the mechanics. Now, thanks to computational sleuthing, they’ve cracked the code. At the nanoscale, fibers change structure mid-spin, optimizing themselves on the fly.

Jacob Graham, the study’s first author, points out that spiders do this instinctively. No fancy lab, no advanced degrees—just eight legs and a knack for molecular engineering. They yank the fiber as it emerges, stretching it into something both elastic and absurdly strong. The more they pull, the tougher it gets.

And humans? Well, humans want in.

Stronger Than Steel, Tougher Than Kevlar, and Completely Biodegradable

For years, researchers have been obsessed with spider silk. Stronger than steel, tougher than Kevlar, yet soft and flexible like rubber. Ideal for body armor, medical sutures, and possibly even space elevators (let’s dream big). The problem? Farming spiders is a logistical nightmare.

Spiders don’t produce silk on demand. They’re territorial, cannibalistic, and generally terrible livestock. So, scientists are trying to manufacture silk instead—without needing millions of eight-legged divas.

Fuzhong Zhang, a study coauthor from Washington University in St. Louis, is engineering microbes to produce synthetic spider silk. If perfected, this could mean biodegradable surgical sutures that dissolve harmlessly in the body, ultra-light fabrics stronger than anything on the market, and maybe—just maybe—blast-resistant armor.

Nature figured it out first. But humans are catching up.

Five Fast Facts

- Spider silk is five times stronger than steel by weight, yet it can stretch up to five times its original length without breaking.

- Researchers once used spider silk to make violin strings—because apparently, music needed a bioengineering upgrade.

- Some species of spiders recycle their own webs by eating them and re-spinning the silk—nature’s version of extreme upcycling.

- The golden orb-weaver spider produces silk with a natural golden hue, making it one of the only “naturally colored” textiles on Earth.

- Scientists have genetically modified goats to produce spider silk proteins in their milk, because bioengineering is officially a sci-fi movie.